CONSUMER ASSESSMENT.

We have consulted many consumers to evaluate the perception of the product in terms of its functionality, how well it dispenses the liquid and how easy it is to use, receiving absolutely positive feedback.

The use of the ITAP tap is very intuitive.

TESTING ON FILLING LINES.

The ITAP tap has been tested and approved for use with most of the BIB and Stand Up Pouch machines available on the market. It has also been tested on manual and high-speed filling lines produced all over the world, including lines by Technibag, Sacmi, Cartobol and Smurfit Kappa.

TRANSPORT.

The objective is to verify the effects transport has on the product. Pallets complete with assembled taps have been shipped to different countries using different means of transport (plane, truck, car, ship), to verify any critical issues arising due to the transport phase. This test was passed successfully.

HOT FILLING.

The ITAP tap has been successfully used in Hot Fill applications worldwide for many years, giving completely positive results. This tap is also suitable for aseptic use with steam or chemical sterilization.

GAMMA IRRADIATION.

The ITAP tap can be treated with gamma irradiation; tests have been carried out up to 40 kGy. In case of extreme conditions due to the variables involved (such as temperature, time, type of filling machine, etc.), it is recommended that compatibility tests be performed to verify that the entire process is appropriate for the intended use.

CRACK RESISTANCE (ESCR).

The purpose of the test is to check if any cracking occurs due to the fragility of the material. This test is performed during the product approval phase. The tap has been tested in contact with different liquids (fruit juices, wine, olive oil) and under critical conditions regarding temperature (hot-cold cycle), light and humidity. It has also been tested in contact with an accelerating fluid (Igepal).

OXYGEN BARRIER SEAL.

ITAP’s objective is not only to facilitate the dosing of a liquid, but also to preserve it for a long time. For this reason, we have developed a tap that provides an optimal barrier against oxidation. Our tests have shown that our tap guarantees the best performance against oxidation, compared to all our competitors.

LEAK TEST.

In the quality control laboratory, other tests are randomly performed under different conditions: temperature, humidity, different mould combinations.

100% of ITAP taps are tested for Leak Tightness, with tests at - 0.5 BAR. Twenty different tests are

performed on each individual tap. After filling, it is best to store the bags with the taps facing upwards, to reduce the pressure on the glands as much as possible.

This procedure should be carried out avoiding any stress or force on the tap itself; for this reason, we suggest handling only the bag.

DRIPPING.

The tap is opened and closed many times to check that it performs well with different types of liquids. The ITAP tap has been developed and compared with competitors’ products to ensure regular dispensing without swirling effects. It has been tested with water, wine, fruit juices and olive oil, giving optimal results in all cases.

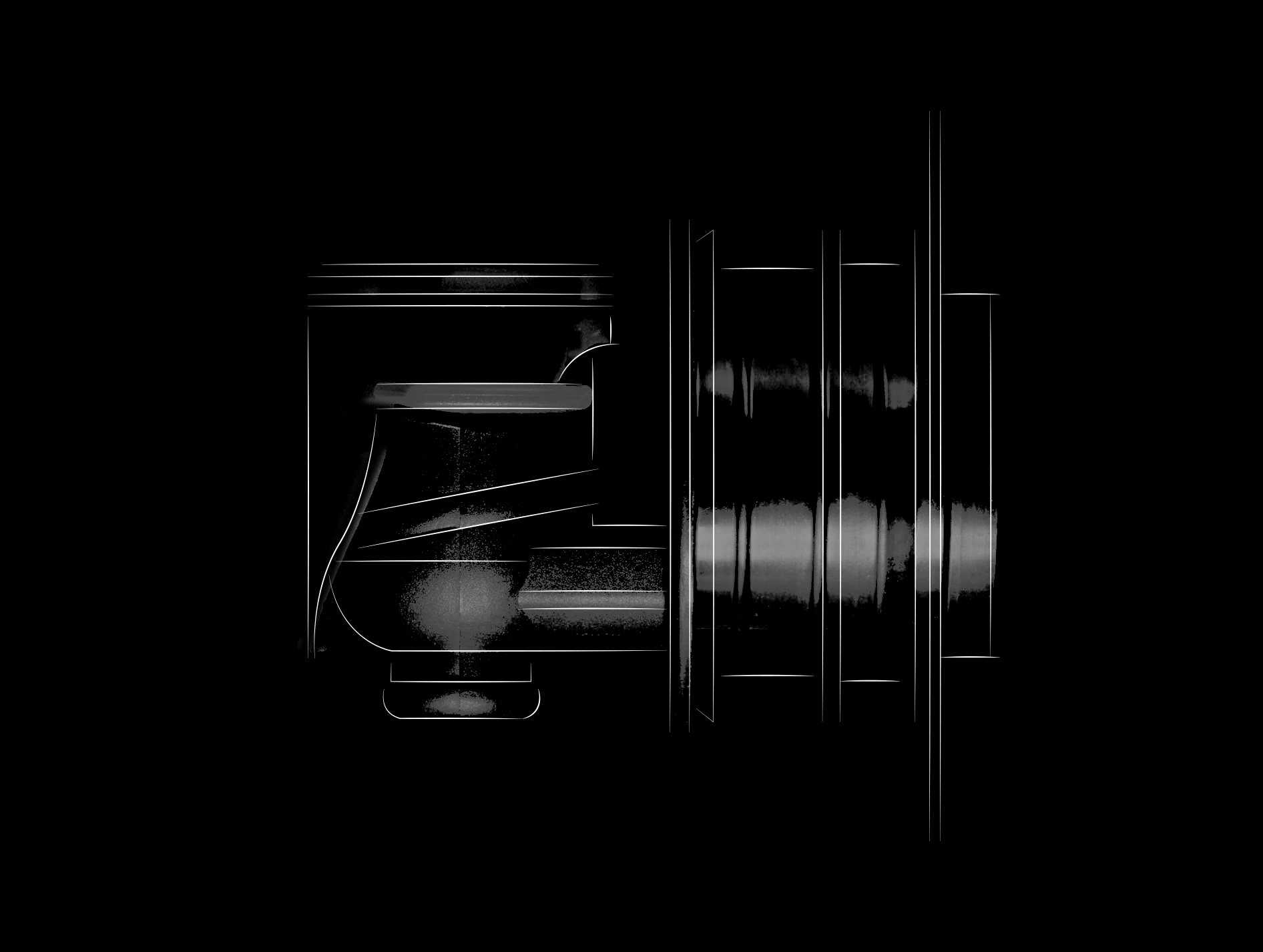

CONTROLLING FORCE.

Controlling force values are important throughout the entire range of movement of the ITAP tap; it is soft enough to activate easily but at the same time has a strong spring effect to ensure the immediate interruption of the dispensing action, guaranteeing a perfect seal.

INSERTION AND REMOVAL.

The force required to insert and remove an ITAP tap is constantly monitored by the quality control laboratory. This also verifies the force of decay and complete adaptation under different and severe conditions.

The ITAP tap displays stable performance under a wide range of conditions, ensuring the best performance in different filling lines and avoiding expensive set up operations.